The PLASMATIC™ is an entry-level, high accuracy, built-to-last plasma cutting system.

AKS PLASMATIC™ tables utilize industry best Hypertherm plasma power supply units and FlashCut Pro user-friendly CNC controls and software, backed by over 100 years of AKS machine building experience, to bring you the new industry standard for performance and durability in a light industrial, entry-level plasma cutting table.

STANDARD FEATURES

- Unitized Construction

- Water Table or Downdraft Table

- Helical Rack and& Pinion Drives

- Replaceable Slat Table System

- Crosshair Laser Pointer

- Magnetic Breakaway Head

- Automatic Torch Height Control

- Easy Plug & Play Self Start-Up

- 19” Touchscreen

- Keyboard and Mouse

- Industrial Panel Operator Console

- FlashCut Pro Software CAD/CAM/CNC

- 2nd FlashCut Pro License for Offline PC

- Quad Core Dedicated Processors

- Maximum Speed 800 ipm

- Single Point On/Off Switch for All Power

- Consumable Start-Up Kit

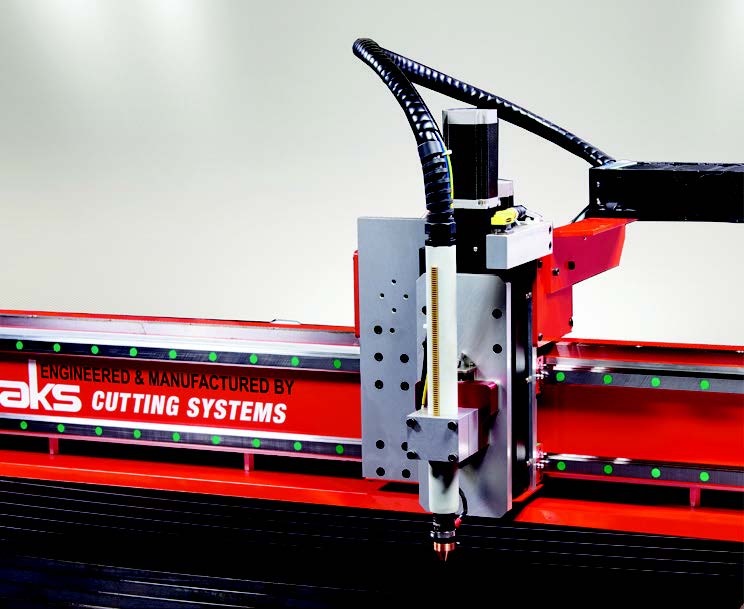

TUCKED DUAL RAILS

Precision linear rails are mounted on the machined surface and integrated with helical rack and pinion and precision bearings.

Z-AXIS CARRIAGE

Automatic lifter is positioned on the z-axis carriage with torch height control (THC), magnetic breakaway head, laser pointer, and plasma torch.

FLASHCUT PRO SOFTWARE

19” Industrial Touchscreen Operator Console with the FlashCut Pro CNC is integrated with all-in-one CAD/CAM/CNC software.

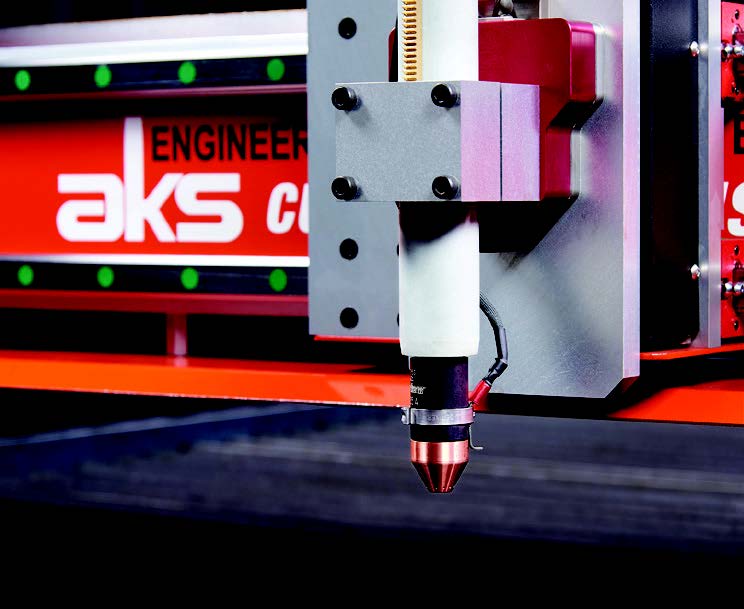

GENUINE HYPERTHERM

Plasma torch and consumables by Hypertherm optimize cut quality, extend consumable life, and boost productivity at the lowest possible operating cost.

DESIGN & BUILD

Rigid and robust design ensures strength, productivity and reliability, with performance and durability far exceeding lighter and less capable models.

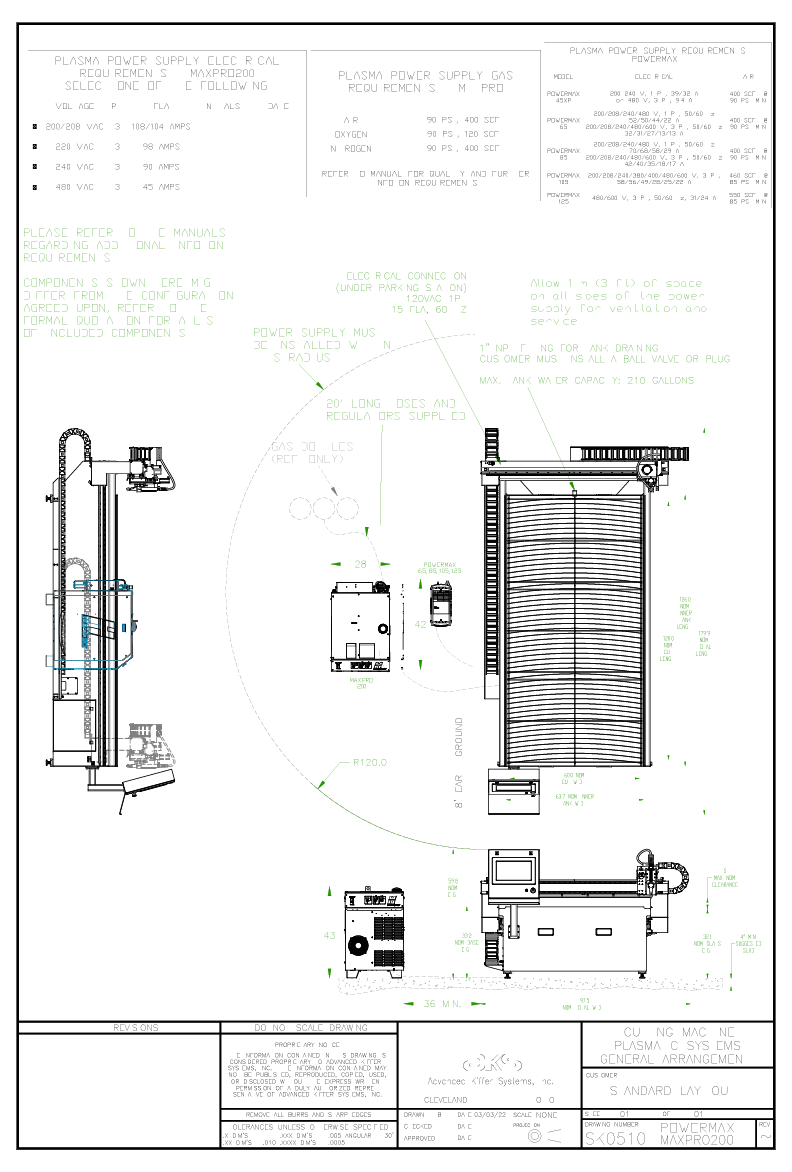

PLASMA SUPPLY

Traditional “air” plasma supply units from Hypertherm including Powermax SYNC 65, 85, 105, 125 and MaxPro 200 Oxygen Plasma System.

CONTROL & SOFTWARE

FlashCut Pro CNC Software is an integrated, all-in-one CAD/CAM/CNC Software, including:

- CAD drawing

- CAD importing drawings

- CAM creating tool paths

- CNC cutting parts accurately

- True Shape Nesting

The FlashCut CNC controller has an integrated power supply with motors and drives using three dedicated microprocessors with parallel processing for full multi-axis interpolation using continuous contouring.

MOTION SYSTEM

The PLASMATIC™ system of motion consists of:

- Single -set-up machined milled surfaces for precision mounting of helical racks

- Precision pinions driven by dual- side planetary gearboxes and industrial stepper motors, without forced engagement from pneumatic or spring load operations

- Precision ground linear bearings

The PLASMATIC™ offers the highest accuracy, smoothest motion, and lowest noise output in its class.